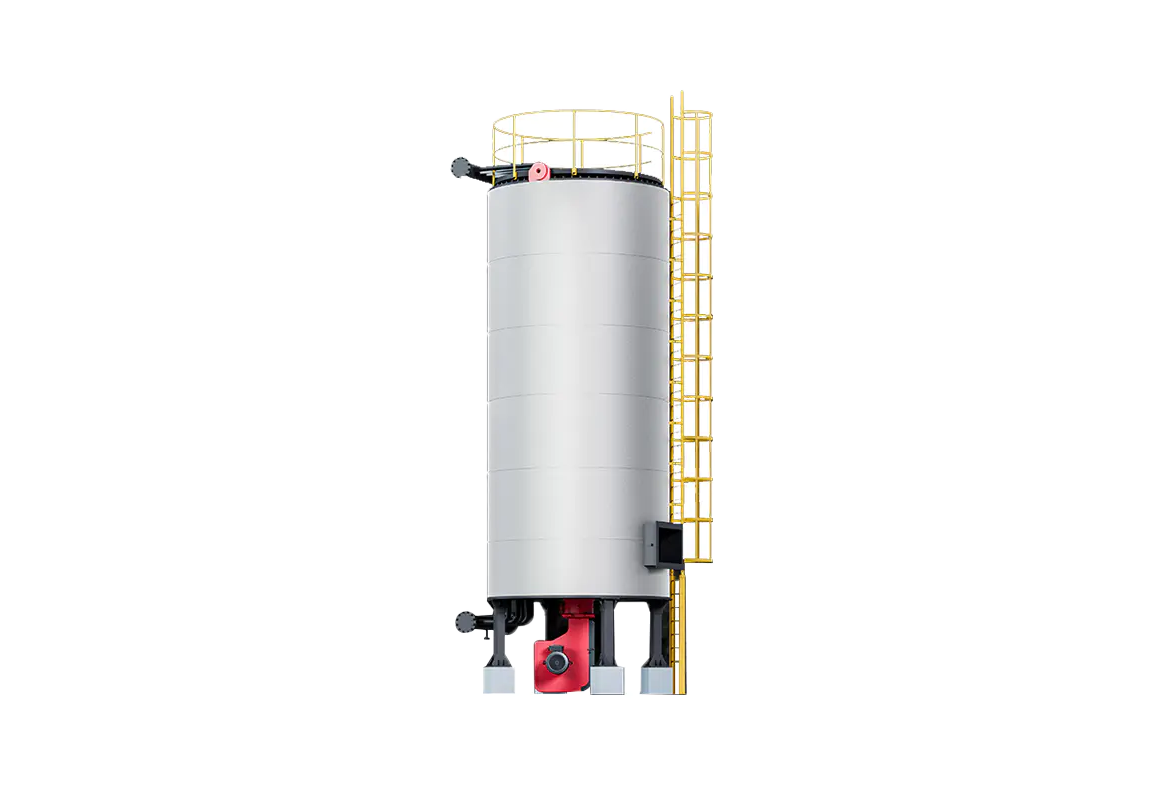

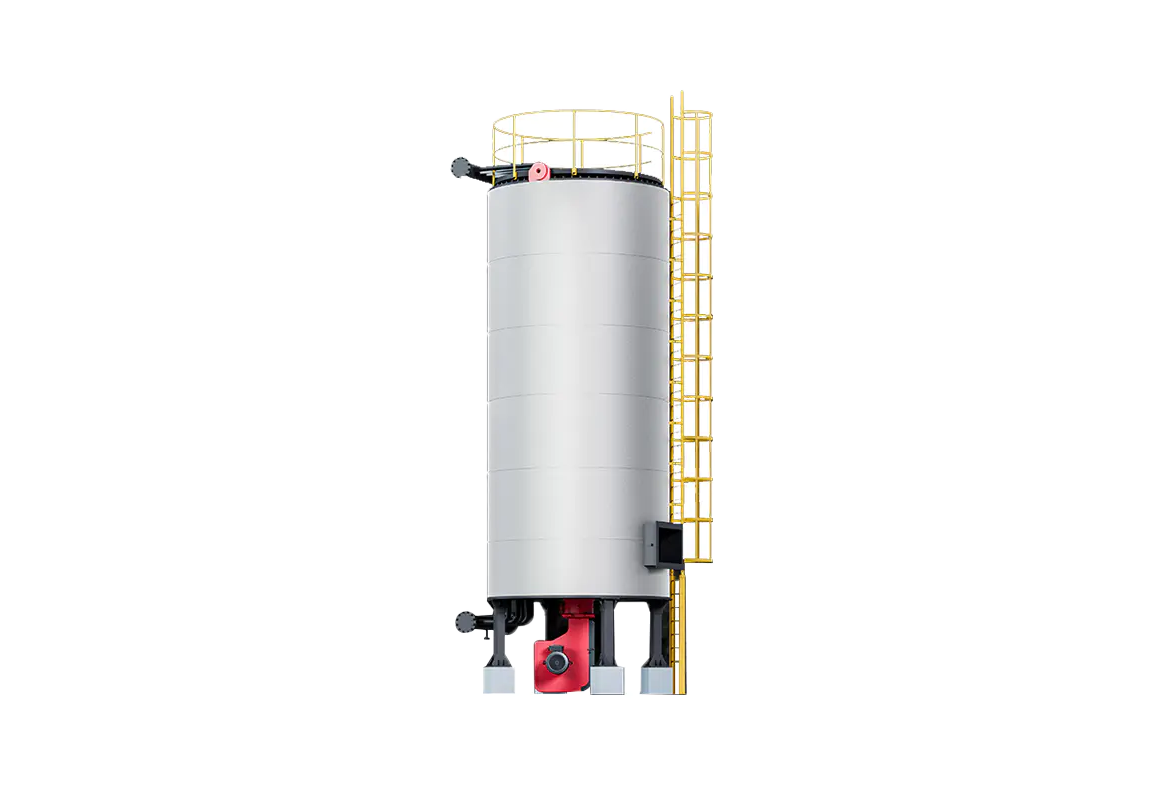

浙江先创能源科技股份有限公司YQ(Y)L 燃气式立式热流体加热器采用三通圆形盘管结构,盘管末端设有锥形盘管,这有效地保护了炉体。

位于锅炉末端的墙壁,还配备了先进的燃烧装置,具有良好的节能和环保性能。该炉膛

具有广泛的燃料适应性、低压力和高温、安全且高效的特点,热效率高达 95%以上。

完善的自动控制系统,可实现无人值守。

浙江先创能源科技股份有限公司

| 型号 | 额定供热能力(kw) | 额定热输出(x10 4kcal/h) | 设计温度(≤℃) | 额定工作压力 (MPa) | 热效率 (%) | 系统装机容量(KW) | 最大运输量 (m)(L×W×H) |

| YY(Q)L-7000Q | 7000 | 600 | 320 | 0.8 | 95 | 140 | 8.0×3.6×4.0 |

| YY(Q)L-8200Q | 8200 | 700 | 320 | 0.8 | 95 | 140 | 8.5×3.7×4.0 |

| YY(Q)L-9400Q | 9400 | 800 | 320 | 1 | 95 | 200 | 9.5×3.8×4.0 |

| YY(Q)L-10500Q | 10500 | 900 | 320 | 1 | 95 | 200 | 10.5×3.8×4.0 |

| YY(Q)L-12000Q | 12000 | 1000 | 320 | 1 | 95 | 240 | 12.4×3.8×4.0 |

| YY(Q)L-14000Q | 14000 | 1200 | 320 | 1 | 95 | 320 | 13.5.×4.0×4.2 |

| YY(Q)L-16500Q | 16500 | 1400 | 320 | 1 | 95 | 380 | 可定制 |

| YY(Q)L-18000Q | 18000 | 1600 | 320 | 1 | 95 | 450 | 可定制 |

| YY(Q)L-21000Q | 21000 | 1800 | 320 | 1 | 95 | 520 | 可定制 |

| YY(Q)L-23300Q | 23300 | 2000 | 320 | 1 | 95 | 600 | 可定制 |

| YY(Q)L-26000Q | 26000 | 2200 | 320 | 1 | 95 | 700 | 可定制 |

| YY(Q)L-29200Q | 29200 | 2500 | 320 | 1 | 95 | 825 | 可定制 |

浙江先创科技股份有限公司

1. 出口集装箱

采用两端法兰及法兰盖的结构,锅炉房内管道的安装与布置简便快捷

2. 在工厂完成整体组装

锅炉经过质量检验并在我厂完成整体组装,便于运输、安装和调试

3. 对流部件

多层紧密排列的管束和多个圆形钢片,可防止烟气短路

4. 检查井和检查门

合理布置检查井和检查门,便于维护、检查和清洁

5. 发光部分

采用三路线圈结构,内圈吸收更多热量,流量更大。在高温环境下运行安全可靠

6. 全自动控制

自动调节并保护锅炉的燃烧以及高位储罐的液位,出口温度和流量可实现无人值守且精确的控制。

请留下您要咨询的信息,我们会尽快联系您!